Client Background:

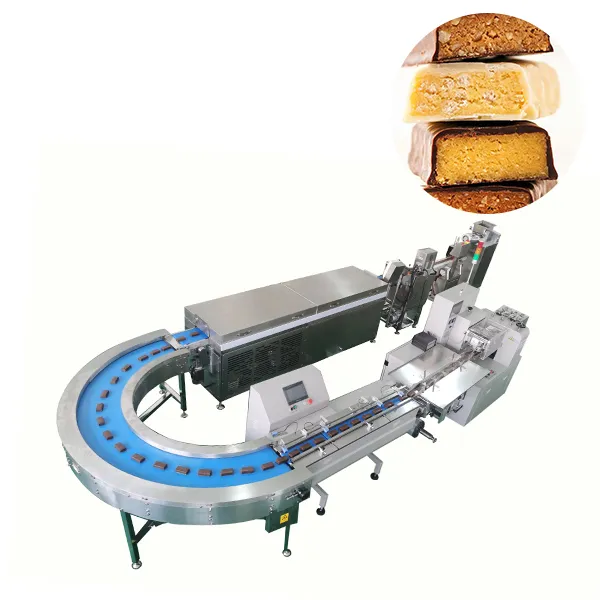

A Ukrainian food manufacturer urgently needed a reliable, high-efficiency chocolate bar production line to meet growing market demand. After extensive comparisons, they chose our advanced fully automated chocolate bar production line solution, which was successfully installed and tested.

Pain Points & Challenges:

- A highly automated, stable chocolate bar production line to overcome challenges such as power fluctuations and labor shortages.

- Compliance with EU food safety standards to guarantee product quality.

- Rapid delivery and installation due to urgent market demand.

Our Solution

We delivered a tailored chocolate bar production line designed to meet these critical requirements:

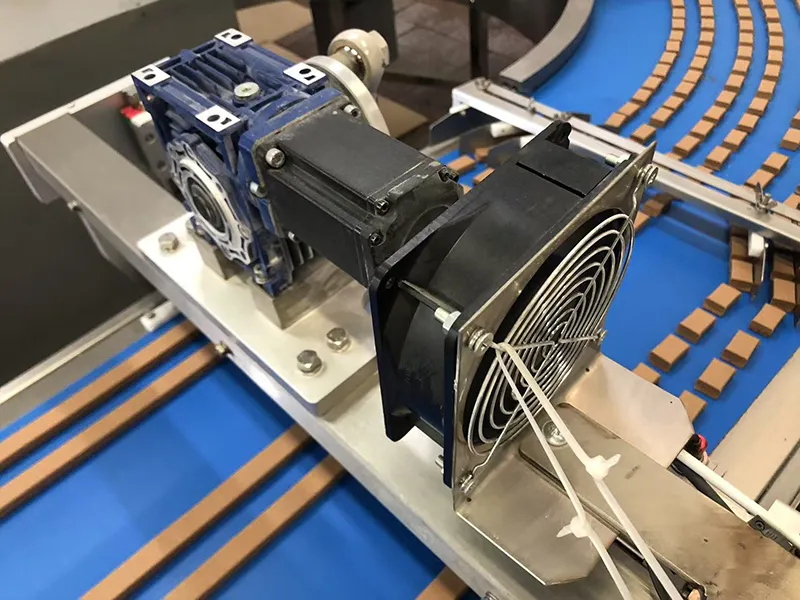

- Fully automated process – Covering mixing, molding, cooling, and packaging, minimizing manual intervention.

- Energy-efficient and stable design – Optimized to handle unstable power supply while maintaining high productivity.

- Fast delivery and installation – Streamlined logistics ensured on-time arrival, with remote setup support from our engineers.

Results & Value:

- Smooth installation: Completed successfully with remote technical guidance.

- Successful trial run: Output and quality exceeded expectations, ensuring client satisfaction.

- Ongoing partnership: The client is now planning to scale up production with additional orders.

Client Feedback

Despite extremely difficult conditions, our chocolate bar equipment delivered stable, efficient performance, enabling rapid recovery of production. The client expressed deep appreciation and looks forward to a long-term partnership.