Due to the characteristics and production process of energy bars, the forming process and machines also vary.

There are two main forming processes:

- Bar Extrusion Process: The P307/P308/P170 protein bar extrusion machine uses extrusion technology to produce protein bars, energy bars, fruit bars, date bars, and coconut bars.

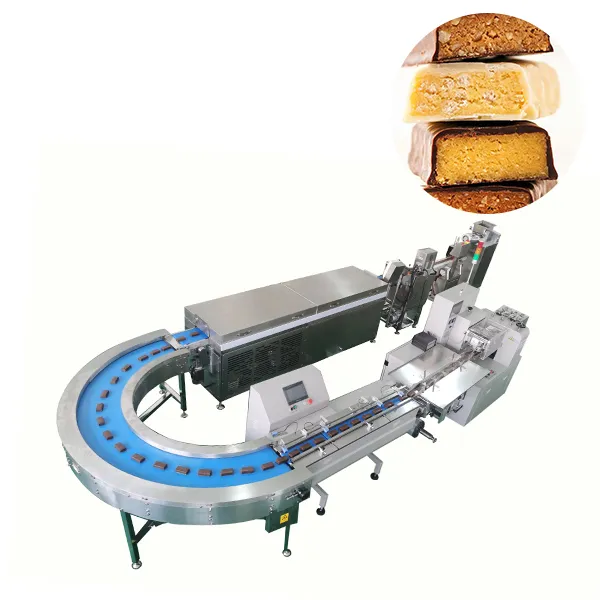

- Bar Slab Forming (Compression) Process: the cereal bar making machine adopts the slab forming process to manufacture cereal bars, granola bars, peanut bars, and sesame bars.

We provide customized solutions to meet your production needs. Contact us for tailored recommendations.

-

- Cereal Bar Making Machine

- Production capacity: 150-250kg

- Power: 5kW

- Voltage: 380V 3 phase

- Dimensions: 4800×920×1200mm

-

- Protein Bar Extrusion Machine (60pcs/min)

- Production capacity: 40-60pcs/min

- Product weight: 10-250g

- Power: 0.6kW

- Voltage: 220V/380V

-

- Protein Bar Extrusion Machine (100pcs/min)

- Production capacity: 20-100pcs/min

- Product weight: 10-250g

- Power: 4kW

- Voltage: 220V/380V

-

- Layered Protein Bar Extrusion Machine

- Production capacity: 60-99pcs/min

- Product weight: 10-250g

- Power: 4.7kW

- Voltage: 380V/50Hz

-

- Multi-Row Protein Bar Extruder

- Production capacity: 120-360pcs/min

- Product weight: 10-250g

- Power: 5.5kW

- Voltage: 380V, three phase