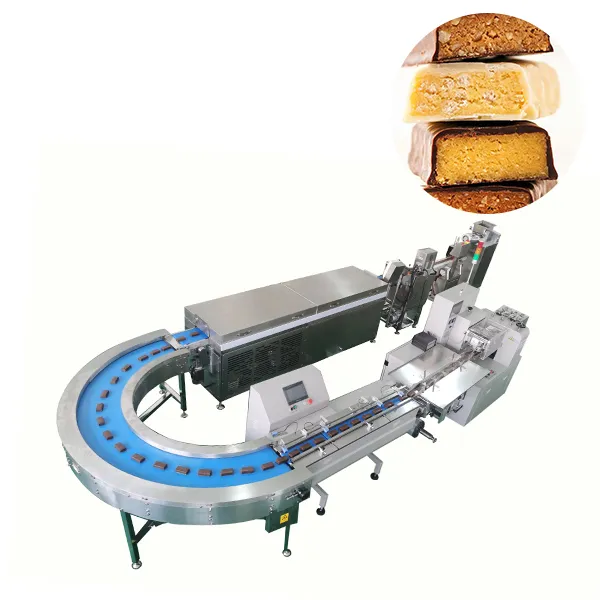

The encrusting process involves placing the filling and dough into separate hoppers. A rectifier guides them through the inner and outer layers , forming a filled product as it is extruded. The inner layer holds the filling, while the outer layer consists of the dough, achieving precise encrusting.

An automatic encrusting machine allows you to adjust the thickness, length, and size of the dough and switch molds to create different product shapes. This versatile machine can produce a variety of stuffed pastries and foods, including kubba (kibbeh), coxinha, arancini, arepas, sandwich cookies, maamoul, kahk cookies, pineapple cakes, mochi, meatballs, filled biscuits, and dual-color cookies. Additional equipment is available for specific food requirements.

Get in touch today to find the right encrusting machine for your production needs.

-

- Automatic Encrusting Machine

- Production capacity: 0-100pcs/min (recommended 60-99pcs/min)

- Product weight: 10g-250g

- Product shape: Ball, cone, round strip, rectangular, serrated, etc.

- Dough and filling ratio: 1:9 to 10:0

-

- Mochi Machine

- Capacity: 10-100pcs/min

- Product weight: 10-125g

- Dough and filling ratio: 1:9 to 10:0

- Power: 3.5kW

-

- Energy Ball Rounder

- Production capacity: 60-90pcs/min

- Product diameter: 10-50mm

- Power: 1kW

- Voltage: 220V, single phase

-

- Energy Ball Coating Machine

- Production capacity: 60-90pcs/min

- Power: 0.75kW

- Voltage: 220V, single phase

- Dimensions (L×W×H): 550×550×700mm

-

- Automatic Stamping Machine

- Production capacity: 60pcs/min

- Product weight: 10-150g

- Power: 0.4kW

- Voltage: 220V, 50Hz, single phase

-

- Automatic Tray Arranging Machine

- Production capacity: 30-350pcs/min

- Tray size: 400×600mm

- Power: 2.1kW

- Voltage: 220V, single phase