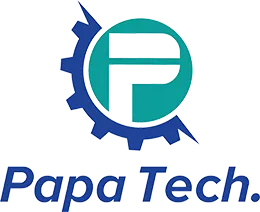

Energy Bar Production Line

Automatic extrusion, cutting and chocolate coating line for energy bars, protein bars, chocolate bars and fruit bars

P307

Energy Bar Production Line

Automatic extrusion, cutting and chocolate coating line for energy bars, protein bars, chocolate bars and fruit bars

- Production capacity 60-90pcs/min

- Product weight 10-250g

- Voltage 220V, single phase

- Power 9kW

- Dimensions 8000×2500×1450mm

- Weight 1300kg

- Product shape bar, round, strip, square, pyramid, bites, etc.

Our energy bar production line includes the protein bar extruder, bar cutter, chocolate enrober, cooling tunnel, 180° turn conveyor, connecting conveyor, and flow wrapping machine. You have the flexibility to select the machines you need to create a tailored production setup.

This line is designed to produce high-quality energy bars efficiently and consistently. With a production capacity of 60-90 bars per minute, it can yield 28,000-30,000 energy bars per day. It’s ideal for medium to small-scale factories. For higher output, we can recommend additional equipment.

- The protein bar cutting machine serves as the bar shaping system, with extrusion nozzles customizable to bar width and height. The machine allows length adjustment of the bars through its cutting screen.

- The chocolate enrobing machine is essential for applying chocolate coatings to bars. It can fully or partially coat the bars and is versatile enough to coat other food items as well.

- The chocolate cooling tunnel is designed for efficient cooling of chocolate coatings. With a powerful 3P refrigeration unit, it can reach temperatures as low as -20℃. The cooling tunnel can also be connected to the protein bar machine to cool sticky bars without chocolate coatings.

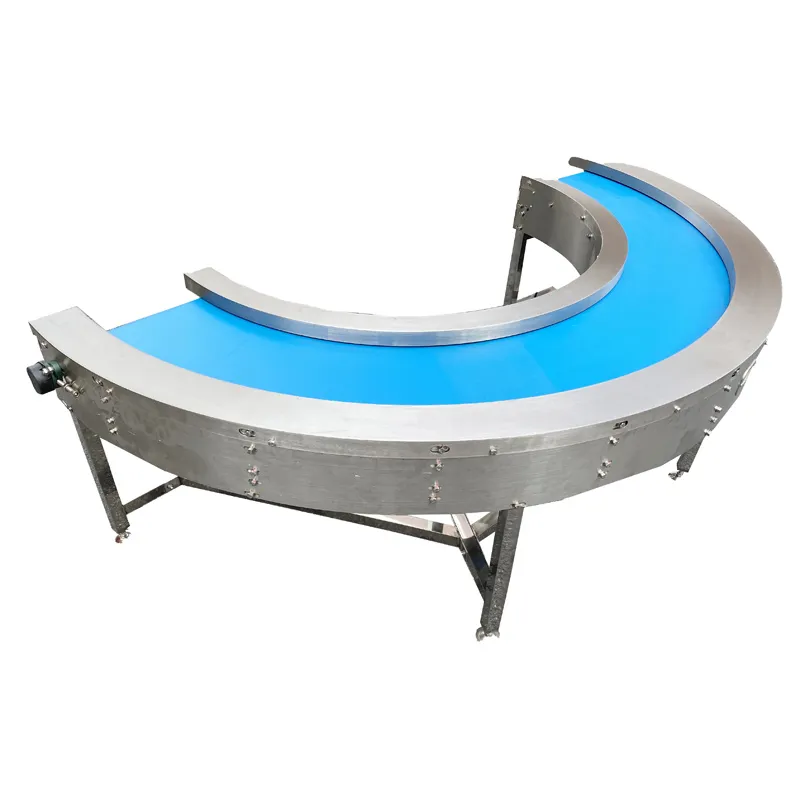

- The 180° turning conveyor links the cooling tunnel with the flow wrapping line to save space. The conveyor’s arc can be customized (e.g., 90°) to accommodate various factory layouts, provided there’s enough space for the protein bar production line.

- The flow wrapping line is equipped with an automatic sensor that arranges and counts bars before packaging. Its bottom-film wrapping method offers excellent protection, particularly for fragile and sticky bars, ensuring the products remain intact and well-shaped.

-

Extruding

-

Enrobing

-

Cooling

-

Conveying

-

Sorting

-

Packaging

P307 Bar Extruder

The protein bar extrusion machine is our fourth-generation model, designed with a horizontal layout to ensure smooth dough movement. It features two PE screws (optional stainless-steel screws) inside a flat feeding hopper, which drive the pre-mixed dough, ensuring uniform distribution before extruding it through a custom nozzle into bar shapes. A separate vertical cutter then slices the bars with precision.

8kg Chocolate Enrobing Machine

The chocolate enrobing machine coats cereal bars, energy bars, protein bars, candy bars, rice bites, wafers, cakes, breads, rolls, and more with a smooth chocolate layer. Designed for precision and efficiency, it ensures even coverage and a high-quality finish. With chocolate melting tank capacities of 8 kg, 15 kg, 30 kg, and 60 kg, you can choose the right machine based on your daily production needs. Pair it with a cooling tunnel or fan cooling conveyor to ensure proper chocolate drying.

3.2m Cooling Tunnel

A cooling tunnel rapidly solidifies the melted chocolate on your products, ensuring they hold their shape before packaging. Typically, the cooling tunnel follows the chocolate enrobing machine, with a packaging machine placed at the end. Our cooling tunnel features a controlled airflow system that maintains a steady and even cooling process, ensuring high-quality results. It can be customized in width and length, with widths ranging from 20 cm to 1200 cm and lengths from 320 cm to 1500 cm.

- Email: info@papaindustrial.com

- Mobile: +86-15221132484