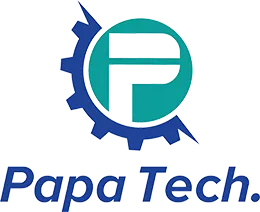

Chocolate Bar Production Line (3 Rows)

Automatic extrusion, chocolate coating and cooling line for energy bars, protein bars, chocolate bars and fruit bars

P307

Chocolate Bar Production Line (3 Rows)

Automatic extrusion, chocolate coating and cooling line for energy bars, protein bars, chocolate bars and fruit bars

- Production capacity 60-180pcs/min

- Product weight 10-250g

- Voltage 220V, single phase

- Power 9kW

- Dimensions 8000×2500×1450mm

- Weight 1300kg

- Product shape bar, round, strip, square, pyramid, bites, etc.

The P307 energy bar production line features an integrated system that includes a protein bar extruder, chocolate enrobing machine, cooling tunnel, 180° turn conveyor, connecting conveyors, metal detector, and flow wrapper. You can select the exact machines that match your production requirements, ensuring your facility operates efficiently and meets your output goals.

This production line uses a three-lane configuration capable of producing up to 180 energy bars per minute. With this setup, you can achieve a daily output of 86,400–129,600 energy bars, making it ideal for large-scale operations.

- Protein Bar Extruder: The extruder can be customized with different nozzles to shape bars of various widths and heights. The length of the bars can also be adjusted using a sizing plate.

- Chocolate Coating Machine: Essential for applying a layer of chocolate to the outside of the bars. This machine offers full or partial chocolate coating and can also coat other types of food products.

- Chocolate Cooling Tunnel: Equipped with a powerful 3P cooling system, this tunnel ensures that the chocolate sets at temperatures as low as -20°C. It can also cool sticky bars that do not have chocolate coatings when connected directly after the protein bar extruder.

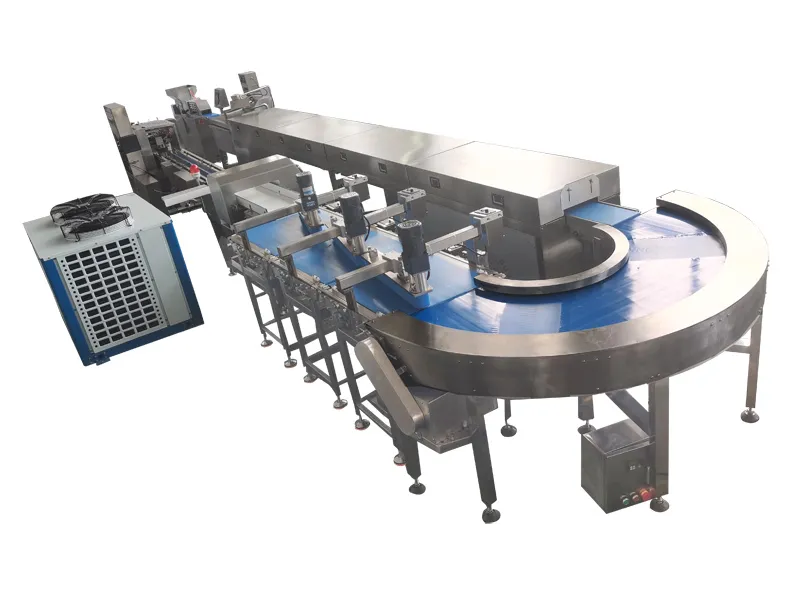

- 180° Turn Conveyor: Connects the cooling tunnel to the flow packaging line, saving valuable factory floor space. The conveyor can be customized to different curves (e.g., 90°) to fit your specific factory layout.

- Flow Packaging Line: Includes sensors for sorting and counting the bars before packaging. This bottom-seal packaging system offers excellent protection against breakage and deformation, particularly for fragile or sticky bars.

-

Extruding

-

Enrobing

-

Cooling

-

Conveying

-

Metal detection

-

Sorting

-

Packaging

P307 Bar Extruder

The protein bar extrusion machine is our fourth-generation model, designed with a horizontal layout to ensure smooth dough movement. It features two PE screws (optional stainless-steel screws) inside a flat feeding hopper, which drive the pre-mixed dough, ensuring uniform distribution before extruding it through a custom nozzle into bar shapes. A separate vertical cutter then slices the bars with precision.

6m Cooling Tunnel

A cooling tunnel rapidly solidifies the melted chocolate on your products, ensuring they hold their shape before packaging. Typically, the cooling tunnel follows the chocolate enrobing machine, with a packaging machine placed at the end. Our cooling tunnel features a controlled airflow system that maintains a steady and even cooling process, ensuring high-quality results.

Metal Detector

Industrial inspection system for detecting metal contaminants in food and other products. This metal detector is installed at the end of the packaging process to detect any metal particles or fragments that may have entered during production, ensuring food safety. It is suitable for products such as protein bars, energy balls, milk, sausages, fresh meat, sauces, fillings, salt, and smoked products.

Horizontal Flow Wrapping Machine

With this horizontal flow wrapping machine, you can efficiently package bread, snack bars, chocolates, block-shaped candies, and other bulk products with ease. Designed for smooth and precise operation, it runs on a servo motor, allowing you to wrap between 35 to 220 packs per minute. The machine also includes a date printing function and lets you customize the conveyor track to fit your product’s size.

- Email: info@papaindustrial.com

- Mobile: +86-15221132484