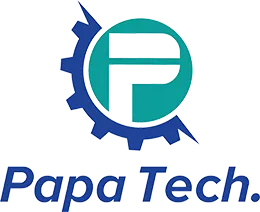

Bread/Pastry Production Line

Automatic dough processing, shaping and encrusting line for various breads and pastries

P886

Bread/Pastry Production Line

Automatic dough processing, shaping and encrusting line for various breads and pastries

- Production capacity 1800-20000pcs/h

- Voltage 220V, single phase

- Power 7.2kW

- Dimensions 6123×1500×1620mm

- Weight 1200kg

- Applications Stuffed bread, toast bread, dinner roll, burger bun, crispy pastry, steamed buns, etc.

PAPA’s bread and pastry production line offers an easy way to produce a variety of baked goods. The system includes machines for dough sheeting, dividing, filling, cutting, and shaping dough. You can adjust each machine to make different shapes and sizes. For example, the dough sheeter flattens dough into smooth sheets, the dividing machine portions it evenly, and the filling machine adds jams, creams, or chocolate. The shaping and cutting machines ensure consistent sizes and shapes, helping you save time and reduce manual work.

With this line, you can make items like baguettes, loaves, rolls, sandwich bread, jam-filled buns, and more. The equipment is made from food-safe materials, making it easy to clean and maintain. This production line is a practical solution for both small bakeries and large production facilities.

- Easy to clean and maintain, with a simple, compact design and low chance of failure.

- Runs smoothly and quietly even at high speeds.

- Safe and simple to operate without the need for manual kneading.

- High production speed and efficiency, with precision electrical controls managing each stage.

- Reliable performance ensures no blockages or dough breakage during production.

- All materials in contact with food (such as hoppers, belts, trays) meet food safety standards.

- The dough is processed through several sheeting stages to improve elasticity, density, and texture.

- Equipped with a Mitsubishi PLC main control system and precise optical sensors, offering a high level of automation.

-

Dough sheeting

-

Dividing

-

Filling

-

Slicing

-

Panning

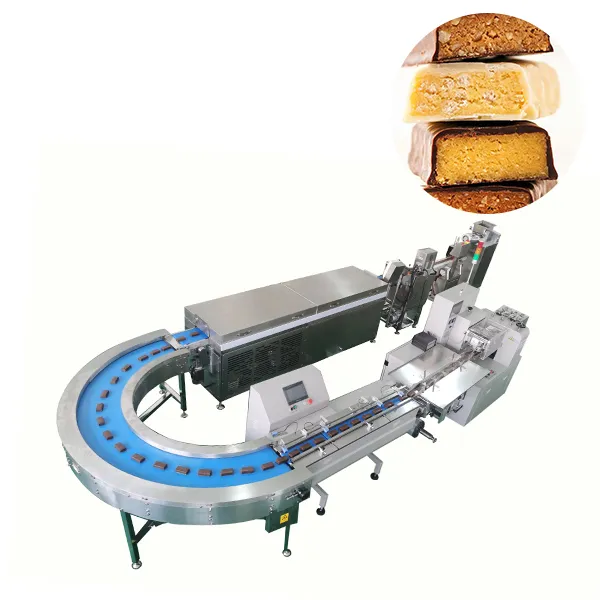

Panning System with Tray Feeder

The automatic panning system, equipped with a tray feeder, is used on the bread production line to arrange finished bread products. It automatically places each bread item onto baking trays at a consistent distance. The panning system can also be used on other food production lines to collect and arrange a variety of other food products.

- Email: info@papaindustrial.com

- Mobile: +86-15221132484