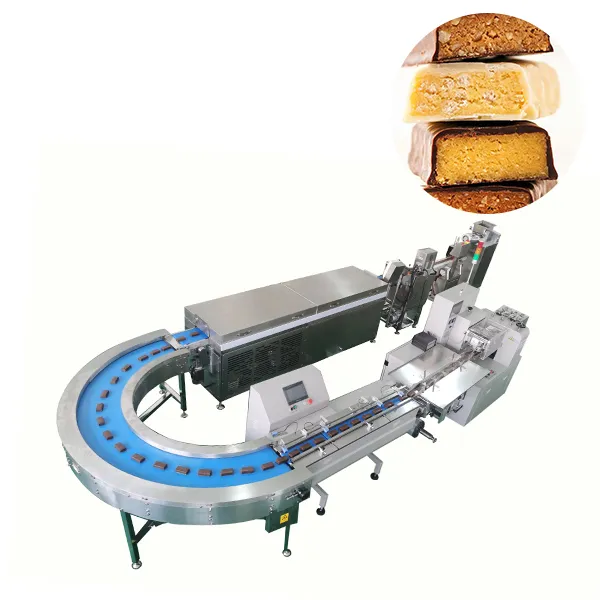

The chocolate enrobing and dipping machine makes it easy to coat your products with a smooth, glossy chocolate layer. Designed to meet your production needs, it applies even chocolate coverage to wafers, egg rolls, sponge cakes, candies, and puffed snacks, ensuring a professional and delicious finish.

With options for full surface coating, single-side coating, and adjustable coverage, you have full control over the chocolate application. Our chocolate coating and dipping machine uses airflow and vibration to fine-tune the thickness, delivering consistent results every time.

Bring efficiency and precision to your chocolate coating process. Contact us to find the best solution for your production line!

-

- Chocolate Enrobing Machine

- Production capacity: 8-60kg/hour

- Max. belt speed: 2m/min

- Heating method: Electric heating

- Total power: 1.8-3.1kW

-

- Cooling Tunnel

- Compressor power: 2.0kW

- Motor power: 0.2kW

- Belt width: 200mm

- Cooling temperature: 0 degree

-

- Chocolate Enrobing and Cooling Machine

- Belt width: 400-1200mm

- Belt speed: 1-10m/min

- Cooling tunnel length: 10-24m

- Refrigerator unit: 2-5 sets

-

- Chocolate Dipping Machine

- Production capacity: 45-70kg/h

- Voltage: AC380V/50Hz

- Motor power: 2-4kW

- Quantity of biscuit clamps: 250pcs