Chocolate Machinery

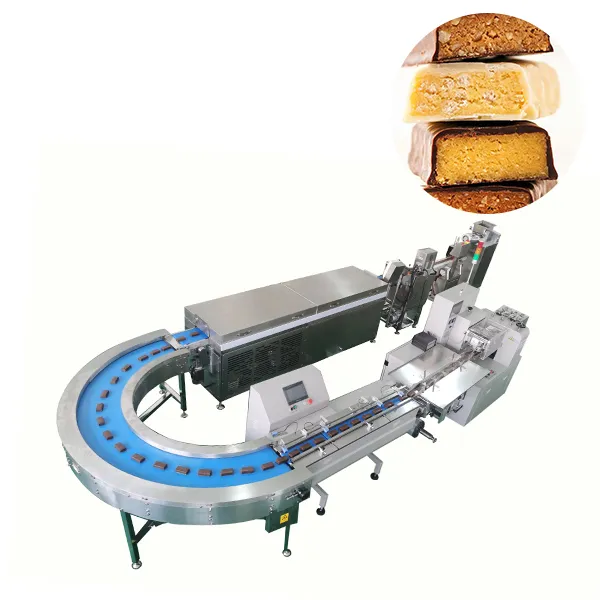

Chocolate Enrobing and Cooling Machine

Enrobing machine with cooling tunnel for coating food products with chocolate

Chocolate Machinery

Chocolate Enrobing and Cooling Machine

Enrobing machine with cooling tunnel for coating food products with chocolate

A high-efficiency solution for chocolate-coated products like candy, energy bars, brittles, cookies, biscuits, cakes, and bread, our industrial chocolate enrobing production line ensures consistent results.

This system includes a chocolate enrobing machine and a cooling tunnel, allowing you to apply multiple layers of chocolate coating with precision. Your products pass through a smooth “chocolate waterfall” for even coating, then through an air curtain and vibration plate to remove excess chocolate before entering the cooling tunnel for solidification.

With different machine configurations available, you can choose the perfect fit for your production needs. Whether you require a 600mm belt width with a 14-meter cooling tunnel, a 400mm belt width with a 10-meter tunnel, a 900mm belt width with a 20-meter tunnel, or a 1200mm belt width with a 24-meter cooling tunnel, we have a solution that matches your production capacity.

Upgrade your chocolate enrobing process with a reliable, high-performance system. Get in touch to find the best setup for your business!

| Model | ||||

| Belt width | 400mm | 600mm | 900mm | 1200mm |

| Belt speed | 1-10m/min | 1-10m/min | 1-10m/min | 1-10m/min |

| Cooling tunnel length | 10m | 14m | 20m | 24m |

| Refrigerator unit | 2 sets | 3 sets | 4 sets | 5 sets |

| Tunnel temperature | 2-10°C | 2-10°C | 2-10°C | 2-10°C |

| Total power | 12.1kW | 20.8kW | 23.8kW | 27.8kW |

| Weight | 2000kg | 2450kg | 3400kg | 4100kg |

| Dimensions | 14200×950×1800mm | 18200×1150×1800mm | 24200×1450×1800mm | 28250×1750×1800mm |

- Simple linear structure for easy installation and maintenance.

- Equipped with high-quality pneumatic, electrical, and operational components from globally recognized brands.

- Removable material tank for effortless cleaning and precise temperature control.

- Photoelectric liquid level control for accurate monitoring.

- Speed regulation with frequency control for smooth operation.

Can you arrange the delivery of the chocolate enrobing machine to my address?

Why choose our chocolate enrobing machine?

- Constructed with stainless steel and a food-grade belt to ensure safety and hygiene.

- Proven durability and stability, trusted by customers worldwide.

- One-year warranty and lifetime service, providing long-term support.

- A dedicated sales team focused on finding the right solution for your needs.

- A wide selection of models, four compact and four industrial sizes—to suit different production requirements.

- Email: info@papaindustrial.com

- Mobile: +86-15221132484