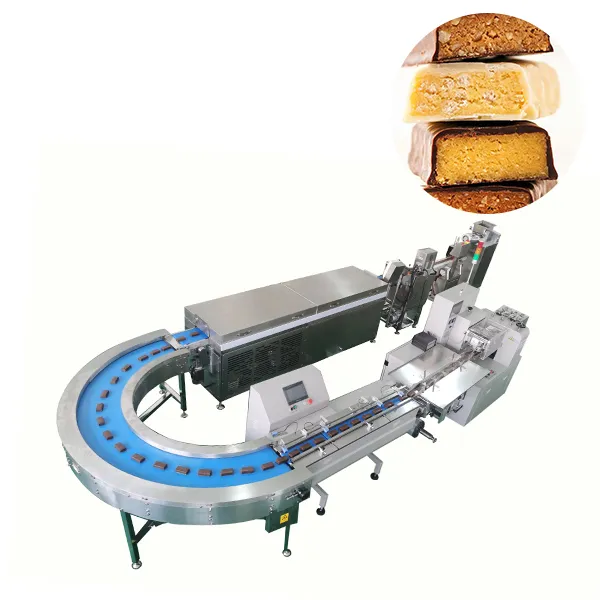

P307 Snack Bar Machine

Date Bar Extrusion Machine

Bar extruder for the production of protein bars

The protein bar extrusion machine is ideal for producing a variety of bar-shaped foods, including date bars, energy bars, fruit bars, protein bars, chocolate bars, vegan bars, cereal bars, muesli bars, nutritious bars, and snack bars.

Contact us today to find the best solution for your production needs!

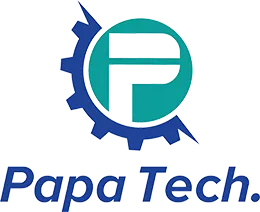

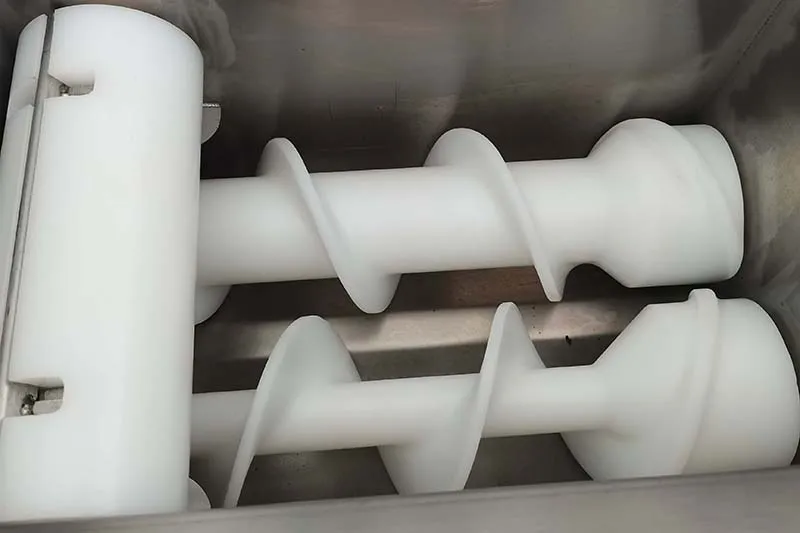

The protein bar extrusion machine is our fourth-generation model, designed with a horizontal layout to ensure smooth dough movement. It features two PE screws (optional stainless-steel screws) inside a flat feeding hopper, which drive the pre-mixed dough, ensuring uniform distribution before extruding it through a custom nozzle into bar shapes. A separate vertical cutter then slices the bars with precision.

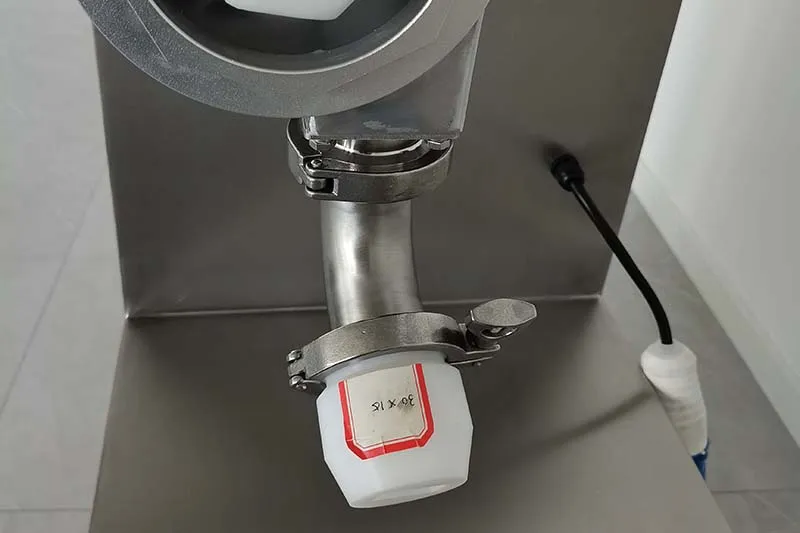

This compact protein bar extruder is controlled by a PLC system and operated through a display panel. All settings, including speed adjustments and memory storage, are managed via a user-friendly touchscreen, making it easy for you to optimize production.

You can use it independently or integrate it with other food processing equipment. It works seamlessly with cooling tunnels for temperature-sensitive products, chocolate enrobing systems for chocolate-coated bars, packaging machines for automated bagging, ovens for additional baking, and ultrasonic cutters for high-volume icebox cookie production.

With a hopper capacity of up to 60 kg, this machine delivers more power compared to similar models on the market, helping you increase efficiency and streamline your production.

What sizes of bars can the protein bar machine produce?

What power supply is required for the protein bar machine?

I haven't made bars before. Can you provide a recipe?

Do you have certifications for the protein bar machine?

Is installation and training required for the protein bar machine?

- Email: info@papaindustrial.com

- Mobile: +86-15221132484