P308 Snack Bar Machine

Protein Bar Extrusion Machine

Bar extruder for the production of protein bars

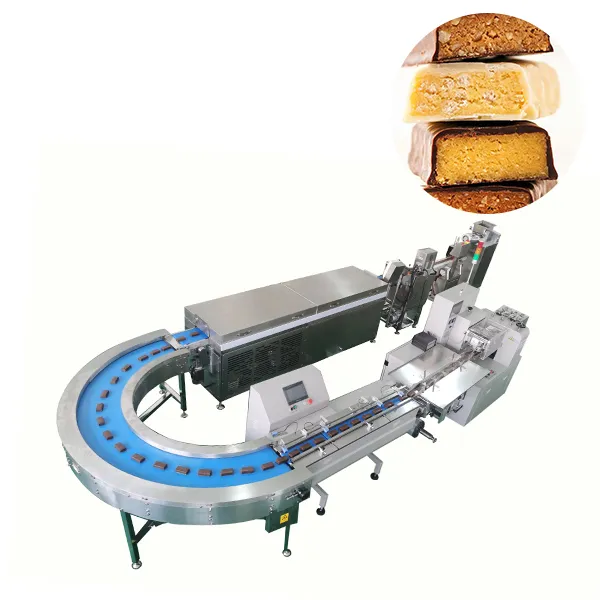

The automatic energy bar making machine is designed to produce dry protein bars with various flavors and ingredients. Equipped with stainless steel screws, it efficiently handles harder food materials. With a production capacity of up to 4,800 protein bars per hour, this protein bar extrusion machine is an excellent choice for large-scale manufacturing.

Get in touch to optimize your protein bar production with the P308 protein bar extrusion machine.

Features

- The machine body and hopper are made of 304 stainless steel.

- Custom-designed nozzles allow for bars of different sizes.

- Capable of producing multiple rows at once, suitable for both small-scale commercial use and large-scale production.

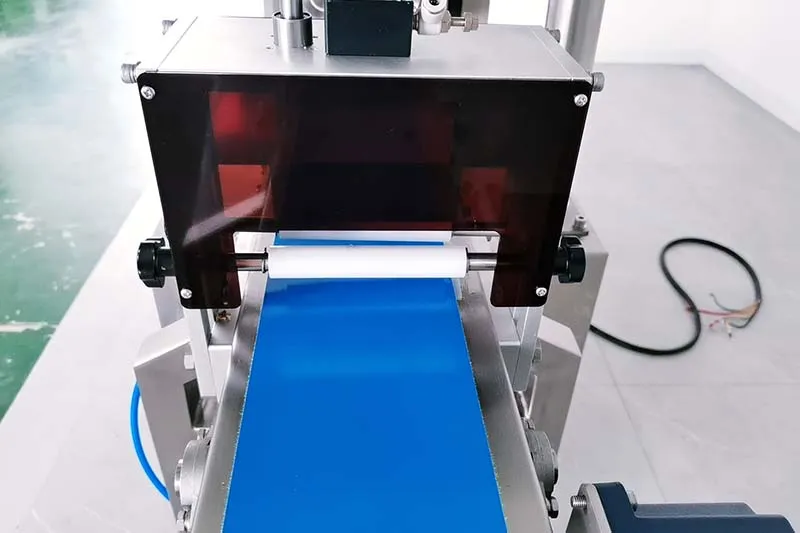

- The extruder and cutter are designed separately, making cleaning and maintenance easy.

- The machine is fully packaged and shipped, requiring no installation—simply connect the power supply.

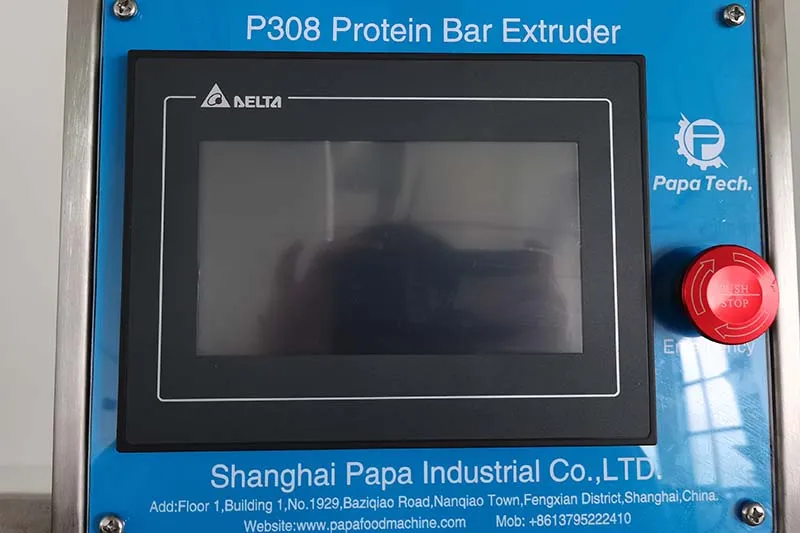

- Automated control allows you to adjust settings easily via the touchscreen.

Key Components

What bar sizes can the protein bar machine produce?

What bar sizes can the protein bar machine produce?

As long as the bar width is within 150 mm, we can customize the nozzle. For larger sizes, we can customize the conveyor belt.

I haven’t produced bars before. Can you provide recipes?

I haven’t produced bars before. Can you provide recipes?

Papa Industrial specializes in manufacturing food processing machines, including protein bar machines, but we are not experts in food bar formulation. However, with over a decade of global experience, particularly in manufacturing protein bar machines for India and the U.S., as well as testing hundreds of snack bars for clients, we can offer some basic recipes. We are also happy to assist in developing formulations tailored to your needs.

Do you have certifications for the protein bar machine?

Do you have certifications for the protein bar machine?

Yes, our protein bar machines are CE-certified. We can also provide specific certifications upon request, such as SASO for Saudi Arabia.

Does the protein bar machine require installation and training?

Does the protein bar machine require installation and training?

If needed, our engineers are available for installation. However, since the machine is compact, it is fully packaged and shipped as a complete unit, requiring no installation. The machine features a fully automated PLC system with a touchscreen, allowing easy operation by adjusting settings digitally. We provide detailed manuals and operational videos for training, along with an online service team for support. If on-site installation and commissioning services are required, we will arrange visa applications and schedule our engineers accordingly.

Related Machines

Let's talk about your food project!

- Email: info@papaindustrial.com

- Mobile: +86-15221132484

Get in Touch